Hydraulische pers | Werkplaatspers | Sicmi PSS NC ( 20 – 150 TON)

Hydraulische pers | Werkplaatspers | Sicmi PSS NC ( 20 – 150 TON)

€8.350 (EUR)

Beschrijving

Getoonde prijs is voor 70T machine incl. V-blokken. Bedrijfsklaar, uit voorraad leverbaar.

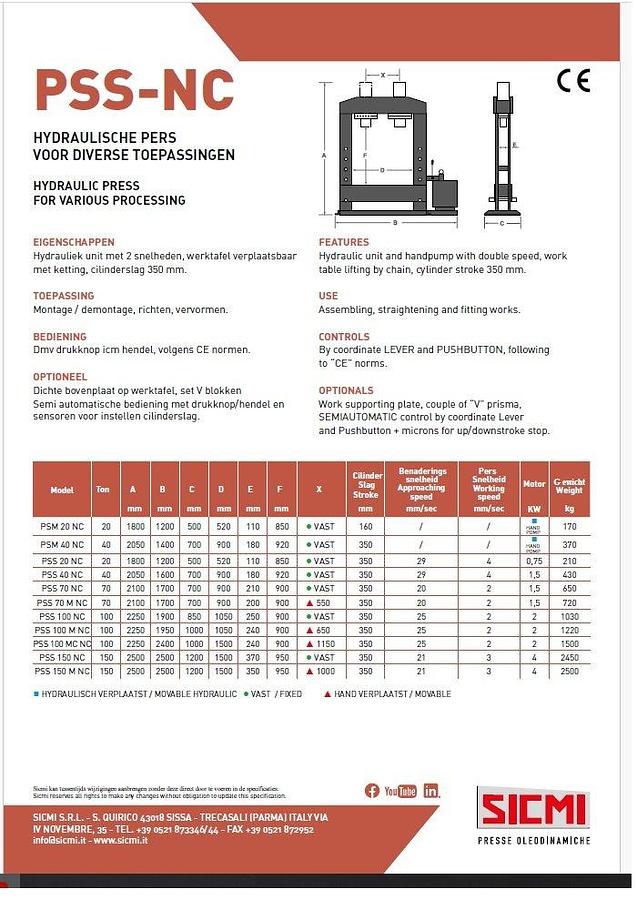

Hydraulische werkplaatspers geschikt voor diverse bewerkingen, zoals het richten van plaatwerk, het monteren en demonteren van lagers, assen, ringen etc., vervormen en allerlei bewerkingen waarbij een grote kracht uitgeoefend moet worden.

Het persframe is gemaakt van volledig gelast gefreesd staal, waardoor de machine zelfs de hoogste drukken kan opnemen. De hydraulische pers PSS-NC is daarom geschikt voor intensief gebruik in onderhouds- en reparatiewerkplaatsen of zelfs in industriële installaties.

Door de grote opening aan de voorzijde kunnen er gemakkelijk lange en/of brede werkstukken geplaatst worden. Het werkoppervlak van de hydraulische werkplaatspers PSS-NC is open waardoor het materiaal door de tafel gestoken kan worden. De dichte bovenplaat is als optie leverbaar.

De PSS-NC-pers is uitgerust met een besturingseenheid met twee snelheden die wordt geactiveerd door gelijktijdig gebruik van de hendel en de drukknop, zoals vereist door de huidige CE-veiligheidsvoorschriften.

Het verplaatsen van het werkplatform gebeurt via een ketting die word verbonden met de hydraulische cilinder en hiermee op/neer gelaten kan worden.

Het werkplatform wordt op de gewenste positie afgesteund met behulp van stalen pennen, waardoor ongewenste bewegingen worden geëlimineerd.

De PSS-NC elektrohydraulische pers is standaard verkrijgbaar van 20 tot 150 ton.

De PSS-NC serie heeft een vaste, niet verplaatsbare cilinder.

Als versie met handpomp in 20 en 40 ton.

Optioneel te verkrijgen voor deze persen:

- Halfautomatische bediening met sensoren die de slag van de cilinder bepalen

- Dichte bovenplaat voor afdekken werkoppervlak

- V-blokken

* Foto’s en video van 70T uitvoering met optionele v-blokken.

Specificaties

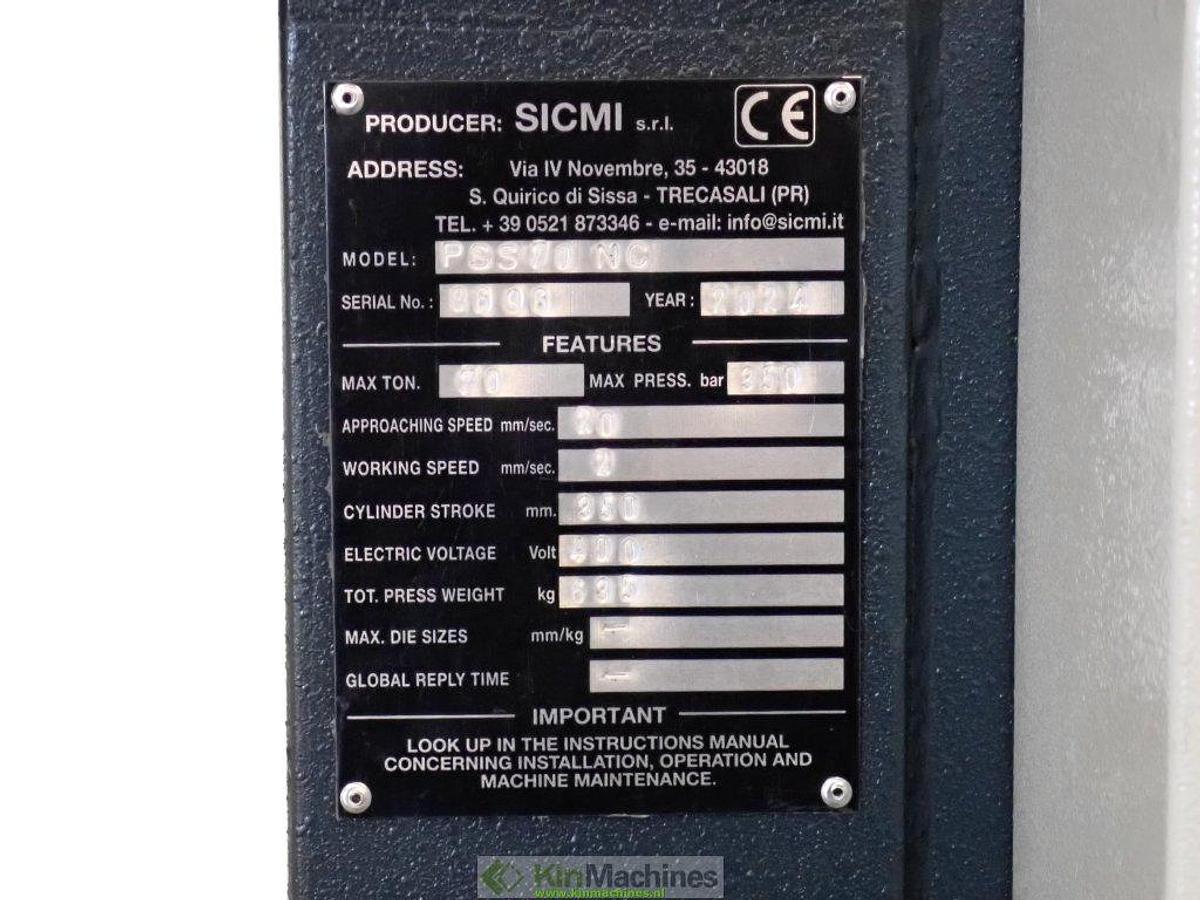

| Fabrikant | Sicmi |

| Model | PSS NC |

| Conditie | Nieuw |

| Soort | Hydraulische pers |

| Capaciteit | Leverbaar in 20 / 40 / 70 / 100 / 150 ton |

| Cilinderslag | 350 mm |

| Netspanning | 400 V (of handbediend) |

| Land van herkomst | Italië |